- Location : Home» Newsroom

Tracing the carbon footprint of cotton garments from seed to garment: Evidence from an empirical study of multiple sites in China

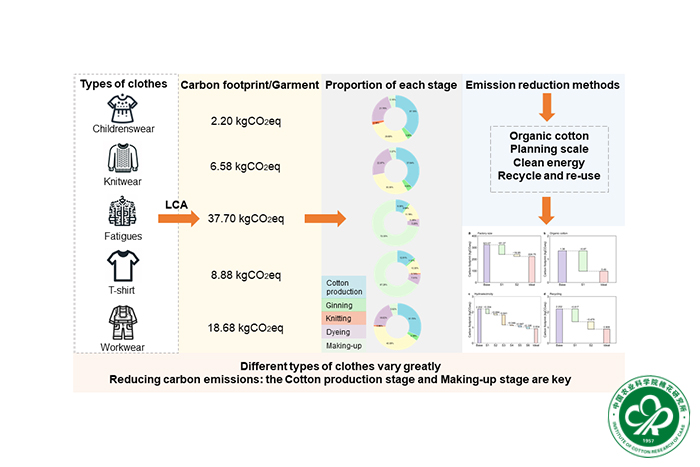

Greenhouse gas (GHG) emissions from Chinese textile production are an important component of global industry, but their intensity varies by textile type. This study addresses the issue of scant research on the carbon footprint of cotton garments in China. Using cross-provincial surveys, emission coefficients, and life cycle assessment (LCA) methods, we analysed the environmental impact of five major types of cotton garments, providing insights into their environmental effects. The carbon footprints significantly differed among the five garments used in this study: childrenswear (2.42 kg CO2eq), knitwear (7.24 kg CO2eq), fatigues (38.64 kg CO2eq), T-shirts (9.18 kg CO2eq), and workwear (20.25 kg CO2eq). At the production stage of cotton, the main components of carbon emissions are electricity, nitrous oxide (N2O) and fertilizers, accounting for 49.18, 18.84 and 14.10 % of emissions, respectively. The impacts of textile production depend on the energy cost, processing technique, and factory size. Additionally, we analysed four optimization scenarios—utilizing clean energy, optimizing factory sizes, using organic cotton, and enhancing recycling, which could reduce carbon footprints by 52.48, 30.43, 35.95 and 62.40 %, respectively. This finding suggests a potential approach for mitigating carbon emissions from cotton textile production and supporting the transformation of the cotton textile industry towards sustainable development, providing a basis for global emission reduction strategies in the cotton textile industry.